Use a comprehensive E/E systems development solution

Today's E/E systems are characterized by increasing complexity. They are reliant on the robust integration of electrical, electronic and software systems. Use Capital, a comprehensive E/E systems development solution, to help you efficiently develop smart products.

Automated

Radically increase automation with a comprehensive model-based digital twin.

Integrated

Seamlessly bridge the boundaries between engineering domains.

Open

Connect solutions in an open ecosystem with flexible, easy-to-use tools.

Explore Capital solution areas

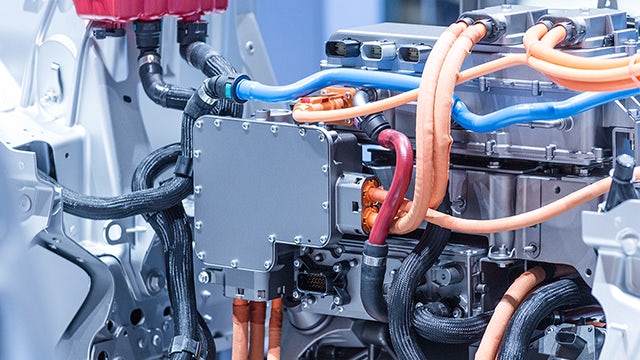

E/E systems development with Capital

Watch this video to learn about our highly differentiated E/E systems development flow that incorporates E/E architecture, electrical systems and embedded software.