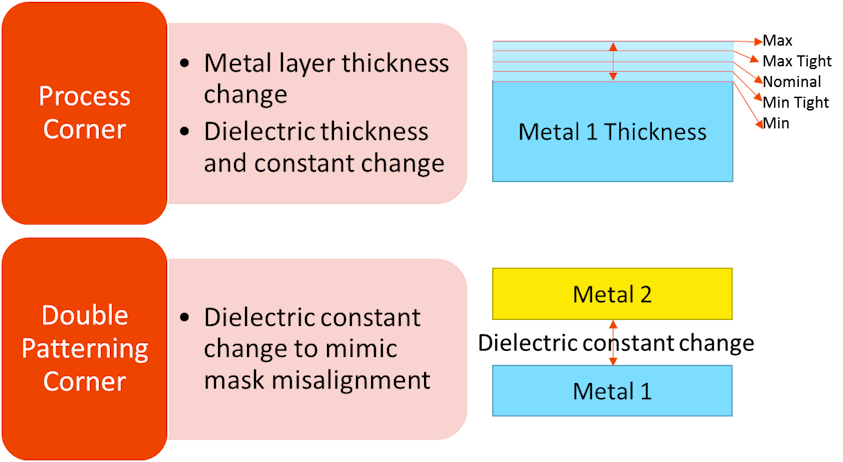

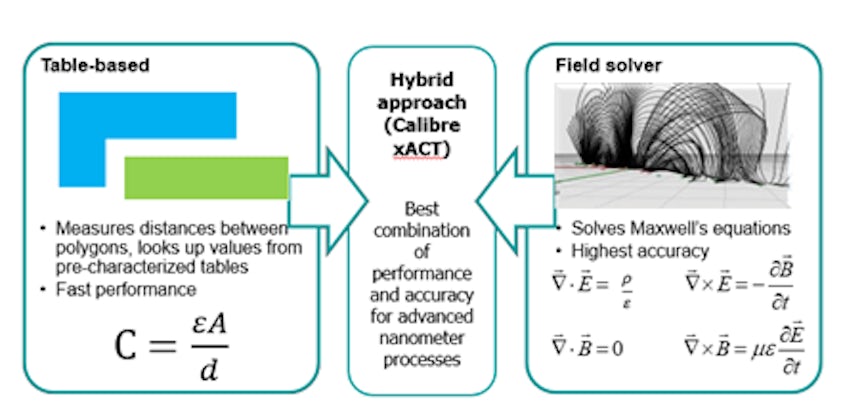

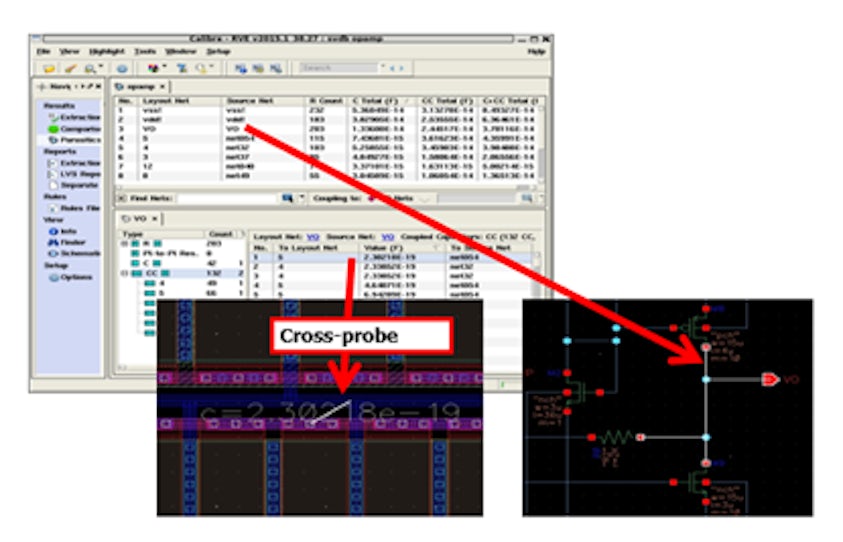

The Calibre xACT solution offers parasitic extraction options for interconnect modeling that ensure accurate capture of parasitic and layout-dependent effects for non-planar devices in advanced node designs, simultaneous multi-corner extraction for efficient processing, and accurate identification of EM current density violations, as well as accurate extraction and modeling for 3D IC package designs.