Non-destructive, repeatable, and standardized testing methods

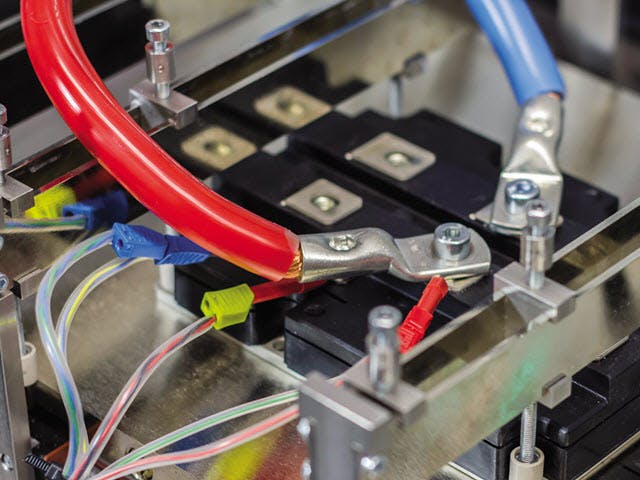

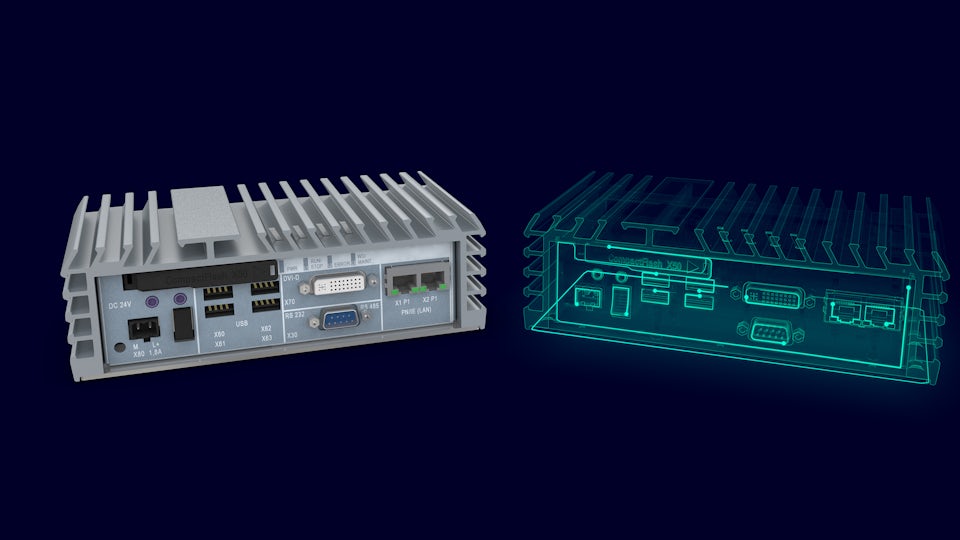

The Simcenter Micred family of hardware and software products is designed to evaluate electronic components’ thermal performance under static and dynamic conditions. The thermal transient testing system works by rapidly changing the applied heating power of a device under test (DUT) and measuring its temperature response. The junction temperature is recorded based on a temperature-sensitive parameter of the user’s choice during the calibration stage. The methods comply with widely adopted industry guidelines, such as JEDEC standards and ECPE Automotive Qualification Guidelines (AQG). The resulting data is used to generate thermal impedance profiles, which provide insight into the thermal behavior of the component.

Determining thermal metrics, thermal reliability, and quality assessment

Impedance profiles are then used to identify potential thermal issues, such as thermal path degradation and any change in thermal resistance can be tracked to a location. It is an excellent tool for diagnosing thermal effects of aging, damages, failure, etc., with real-time detection of wire bond breaks, solder fatigue, die, and substrate cracks.

High fidelity across a wide spectrum of applications

Simcenter Micred testing tools offer a range of systems designed to meet the needs of different applications and industries. These systems feature advanced measurement and control technologies with high accuracy, speed, and precision. They are used by research centers as well as in semiconductor, consumer electronics, automotive, and LED industries during component engineering, prototyping, and testing.

A legacy of innovation

The Simcenter Micred family was initially developed by researchers at the Department of Electron Devices at Budapest University of Technology and Economics (BME). Siemens continues to carry this legacy of innovation forward.

Semiconductor package thermal characterization – thermal metrics, reliability to quality

Watch this on-demand webinar on thermal characterization using thermal transient measurement technology.