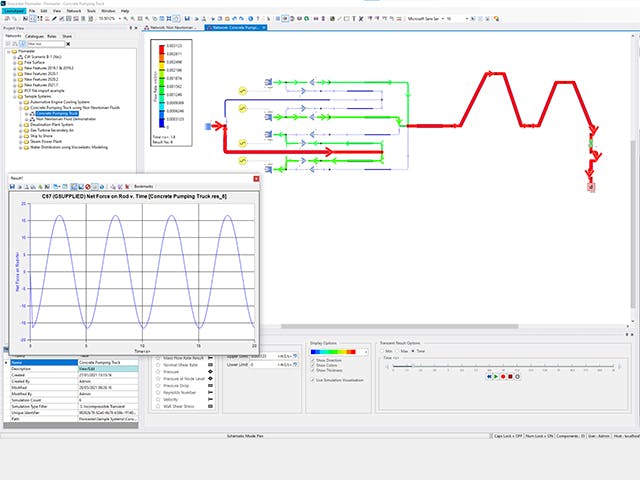

Simcenter Flomaster offers a comprehensive simulation toolset for designing, commissioning and operating thermo-fluid systems. It can connect to PLM, CAD, simulation and industrial IoT to embrace digital transformation.

Reduce time-to-market with thermo-fluid system simulation

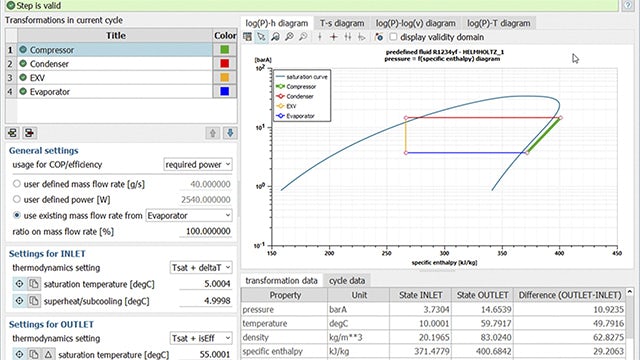

Simcenter Flomaster is a leading simulation tool for fluids engineering and offers reliable and accurate solvers and best-in-class in-built correlations. This means that you can effectively size gas, liquid and two-phase systems and components to achieve maximum efficiency. With the same virtual model, you can analyze dynamic events such as different operating conditions, failure and emergency scenarios to ensure safety.

Design, commission and operate thermo-fluid piping systems

Simcenter Flomaster offers a comprehensive simulation toolset for designing, commissioning and operating thermo-fluid piping systems. This means that the digital twin of the system developed in the engineering phase can be reused during operation for virtual sensing and on-line monitoring to improve efficiency and ensure safety. Simcenter Flomaster can connect to other relevant tools and platforms including PLM, CAD, simulation and industrial IoT allowing you to embrace digital transformation and innovate quickly.