Simcenter E-Machine Design enables you to quickly develop electric machine designs via its template-driven user interface, reducing development time and costs.

Model the complexity – tuned accuracy as appropriate

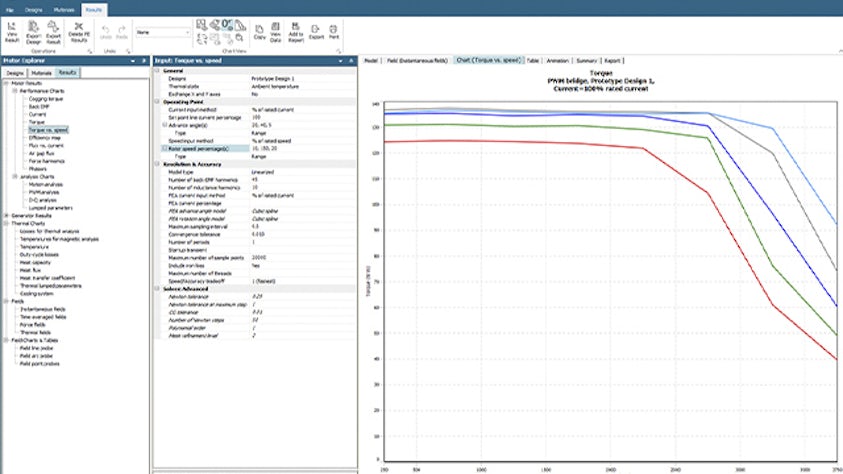

Simcenter E-Machine Design is the only software that allows you to select from analytical EMAG, calibrated analytical EMAG, or Finite Element Method [FEM] EMAG experiments; this versatility allows you to tune the accuracy and time of your performance data collection to the appropriate stage of the design.

Go faster – with ready-made templates

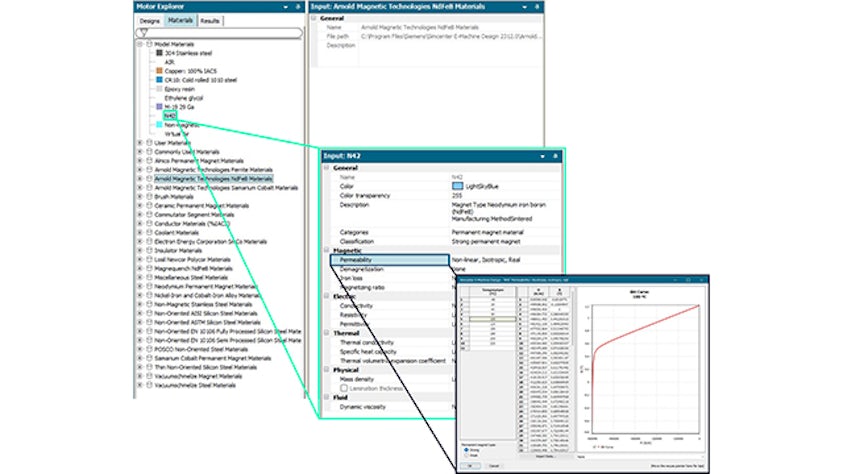

Remove the need for a FEM expert and the complicated process of setting up a model, refining the mesh, defining your desired experiment, and reviewing it. Instead, use our template-driven software to execute a wide range of experiments automatically.

Initiate your idea, clearly define it and quickly review its performance, reducing reliance on multiple physical prototypes.

Explore the possibilities – Comprehensive solution

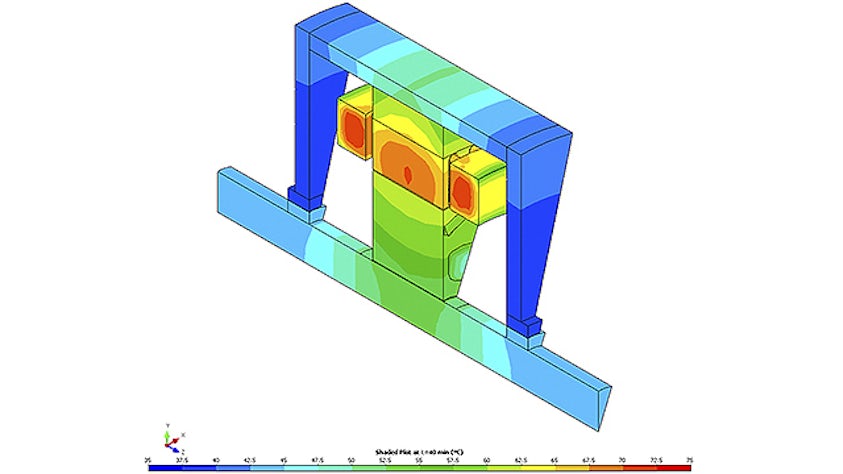

The only product on the market that provides a comprehensive solution for reviewing machine performance at “operating conditions.” You can avoid potential failures using automatic, coupled magneto-thermal effects from the start. There is no data file or geometry exchange to get the coupling which eliminates potential user errors.

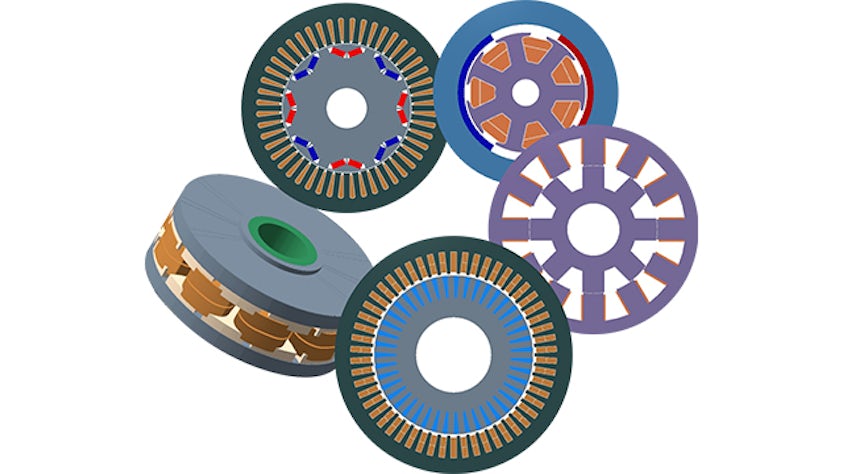

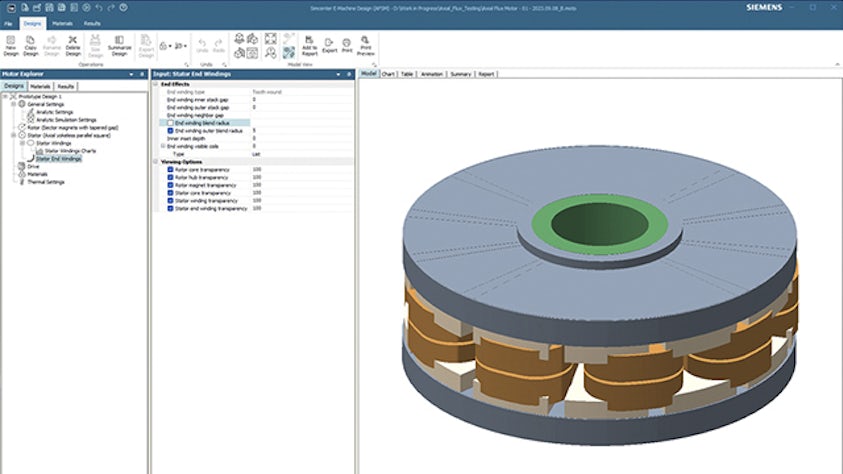

This is the only machine design tool that offers parameterized templates and modeling capabilities for both radial and axial flux machines.

Furthermore, E-Machine Design seamlessly connects to optimization or design exploration with the Simcenter HEEDS product with a specifically designated portal.

Stay integrated – with Simcenter Xcelerator

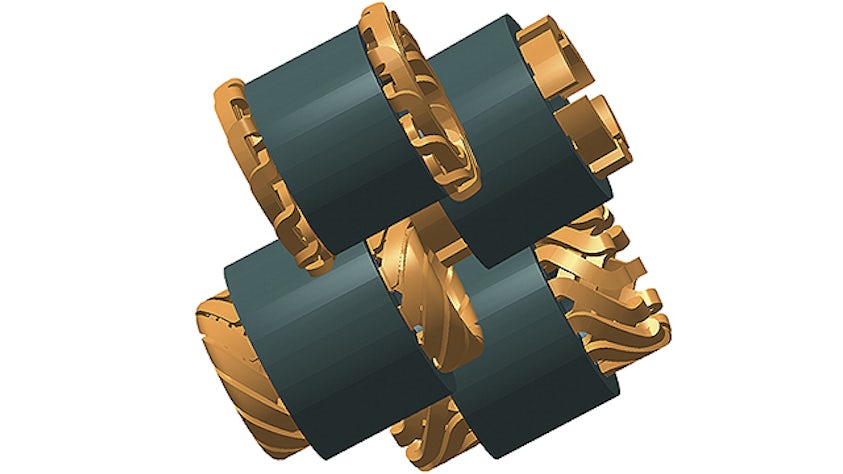

To produce a high-end electric vehicle that is both efficient and silent requires a team of engineers working on the motor and its housing, the transmission, and beyond to understand the vehicle’s entire NVH performance. Simcenter tools can simulate all of these features and their native file formats enable updates to the design to be available to all engineers, ensuring everyone is always working on the latest files.

Accelerate, innovate, and optimize your electric machine design process

Simcenter E-Machine Design is a new product built upon the shoulders of giants as it takes the best of Simcenter SPEED, Simcenter Motorsolve and Simcenter MAGNET for replicating electric machine experiments.